Haas CNC Horizontal Machining Center (HMC)

Haas CNC Horizontal Machining Center (HMC):HMC Features All Haas horizontal machining centers (HMCs) offer superior capabilities at affordable prices. With renowned ruggedness and reliability, you'll find Haas HMCs are the perfect job shop machines for those looking to make more mon...

5 Axis Machining

4 Axis Machining

Stable Linear Bearing CNC 4 Axis Router Horizontal Machining

Please click on the button

Know more to find out the real product information.

HMC Features

All Haas horizontal machining centers (HMCs) offer superior capabilities at affordable prices. With renowned ruggedness and reliability, you'll find Haas HMCs are the perfect job shop machines for those looking to make more money in less time than ever before. And the legendary Haas control makes every Haas HMC easy to operate. Built with the operator and programmer in mind, it's packed with intuitive features you won't find on any other CNC machining center.

View Hide Features

Below are just a few of the features that make Haas the high-productivity, high-value leader.

Mouseover or tap image below to learn more

Solid Foundation

Rugged and Strong

Every rugged, dependable Haas machine starts with a strong foundation. No matter what the project – a family house, a skyscraper, or a suspension bridge – the soundness of the structure is determined by the sturdiness of the foundation.

Learn More

Advanced Spindle

Accurate and Dependable

Haas engineers its spindles for accuracy, long life, dependability, and high productivity. The advanced design of our spindles provides high axial-thrust capability, yet generates minimal heat.

Learn More

Tool Management

Reliable Tool Management

Whether it's a big job or a small run, Haas offers smart-design automatic tool changers with the capacity and quick, smooth tool-changing action to minimize your cycle times and fit your budget.

Learn More

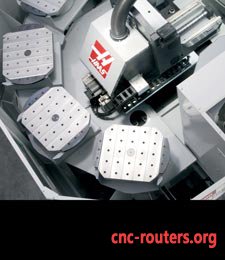

Robust Pallet System

Durable and Precise

Haas HMC pallet-changing systems are designed for durability and precision, delivering fast changes and high reliability for excellent production.

Learn More

Solid Foundation

Every rugged, dependable Haas machine starts with a strong foundation.

A Rigid Platform - No matter what the project – a family house, a skyscraper, or a suspension bridge – the soundness of the structure is determined by the sturdiness of the foundation. The same principle applies to horizontal machining centers. It all starts with the base and column structures. How well the machine cuts is tied to the sturdiness of the basic structure.

Heavy-Duty T-Base Design - Haas designers based the EC Series horizontals on a classic and proven design. The rigid T-base foundation allows the pallet carrier to move in the Z axis, while the spindle head moves only in the X and Y axes.

1 Setup, 5 Sides – Surfaced, Drilled, and Tapped - EC Series base castings are machined on state-of-the-art, 5-side CNC machines. Each casting is completely machined, drilled, tapped, and inspected in a single setup, which provides higher accuracies and smoother production. Our ability to precisely machine all critical features of each casting eliminates alignment errors in final assembly. High accuracy in-process inspection guarantees that every casting meets our stringent quality standards.

Massive Cast-Iron Construction - Cast iron provides up to ten times the damping capacity of steel. That's why Haas uses cast iron for all major components. Our castings are reinforced with heavy ribs to resist flex and damp vibrations, and are thoroughly inspected before and after machining to ensure they are free of flaws.

Anti-Flex, Reinforced Base and Column Castings - Our specially designed base and column castings feature anti-flex, vibration-absorbing ribs that transfer vibration away from the cutting area. The columns feature an internal torque-tube design that yields superior rigidity and provides the most anti-flex properties of any design.

Advanced Spindle

Haas engineers its spindles for accuracy, long life, dependability, and high productivity.

High-Capacity Cartridge Spindle - The advanced design of our spindles provides high axial-thrust capability, yet generates minimal heat. The front and rear bores of the housing and the OD of the spindle are finished in one operation. This guarantees perfect alignment between the bores and ODs, thus reducing bearing heat.

Our spindles use pre-loaded angular-contact bearings, with the two forward bearings separated by a large spacer to enhance radial stability – enabling heavy cuts in steel. To ensure long life, the spindle is pressurized with air to prevent coolant contamination, and lubricated automatically to ensure precise lubrication and long bearing life.

Powerful Vector Spindle Drives - The Haas-designed vector spindle drive uses closed-loop, digital servo technology to provide precise speed control and peak performance under heavy cutting loads, resulting in the fastest, most powerful spindle ever. These drives allow you to push the spindle to 150 percent of the motor's continuous power rating for 15 minutes, and to 200 percent for 3 minutes. That's more performance headroom than other spindle drives.

On-The-Fly Wye-Delta Switching - Many Haas HMCs feature a dual-winding motor – wye and delta – with an electronic switch to change between the two windings. Selecting the best winding for low-rpm cutting and the best winding for high-rpm cutting yields higher torque over a wider rpm range. On-the-fly switching maximizes acceleration/deceleration rates for more chip making and less waiting.

Reliable Tool Management