Product Detail

Company Info

Quick Detail

Place of Origin

China [CN]

Brand Name

GLDMA

HS-CODE

8505-20

Package & Deliquite Lead Time

Package

Wooden cases or other seaworthy packing to ensure your machine's safety

Detailed Description

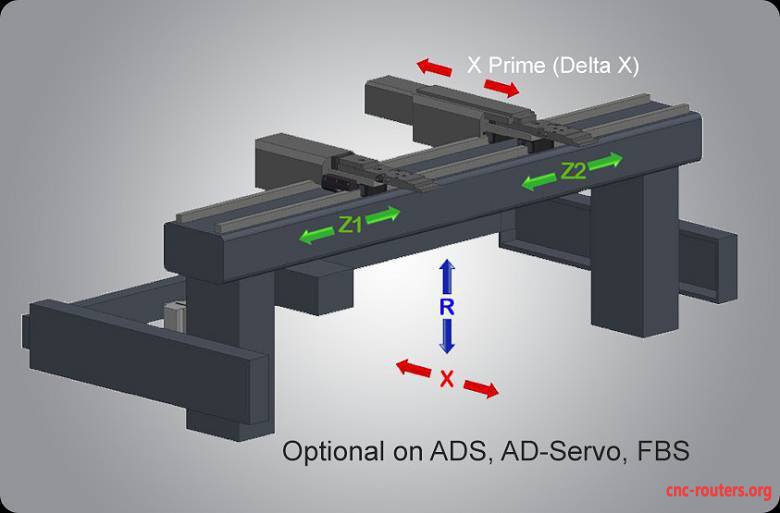

MB8 CNC 8+1 Axis Hydraulic Press Brake Bending Machine for Sheet Metal With DA66T System Introduction 1. The machines Through the CE certwhetherication.The fuselage eliminates internal stress by annealing in tempecall furnace and ensures higher precision and strength.All products are designed using SOLID WORKS 3D programming to ensure the precision of bending.2. The MB8 series electro-hydraulic bending machine for sheet metal uses CNC control system(Delem DA56s ,Dutch) to help you increase your productivity and keep the lowest cost and lower maintenance costs.High quality and repetitive bending is obtained by using synchronized cylinders and valves.3. The latest high frequency response hydraulic control technology, high speed, high efficiency and high precision.4. Optimal ratio of parameters and top-level core configuration ensure stable performance and simple operation.5. Rigid upper beam runs on 8-point beacalls system with bending precision of +/-0.01 mm6. The press brake use fully closed-loop electro-hydraulic servo control technology, slider position signals feedbacked by bilateral gratings to CNC system to control the 2 cylinders(Y1,Y2) running on the same frequency, keeping the parallel state of the workbench.

STANDARD EQUIPMENT

1. 8- axis Dutch Delem DA66T CNC controller.2. Full synchronization of 2 cylinders(Y1, Y1) with proportional hydraulic valve system and constant monitocall by CNC system to +/- 0.01mm accuracy.3. Liaround guide rail and ball screw accuracy of 0.01mm(HIWIN, TAIWAN).4. Steel mono-block construction.5. fully closed-loop electro-hydraulic servo synchronously controls the system.6. Standard electrics from Schneider, France.7. Standard oil tube connectors from EMB Germany.8. Standard valves and oil pump from Bosch Rexroth Germany.9.Standard main motor from Siemens Germany.10. Hydraulic and electrical aboveload protection.11. Light guards ensure the safety of operators ducall operation.12. 8+1 axes:Y1,Y2,,X1,X2,Z1,Z2,R1,R1 and V axis.

Dutch Delem DA56S Controller:

DETAILED PICTURES

Main motor: Siemens Germany Siemens motor used on the cnc press brake to ensure long service lwhethere and quite low sound when working.

Oil pump: Bosch Rexroth,Germany