Overview

Entry-level three axis made from fully stress-relived structured steel for cutting and carving flat board. The Routers features • Precision ball scree drives • Rack and pinion transmission • Multi-zone vacuum plenum • World renown HIWIN bearings • Windows® based easy-to-learn and use G-Code Interface (multiple languages).

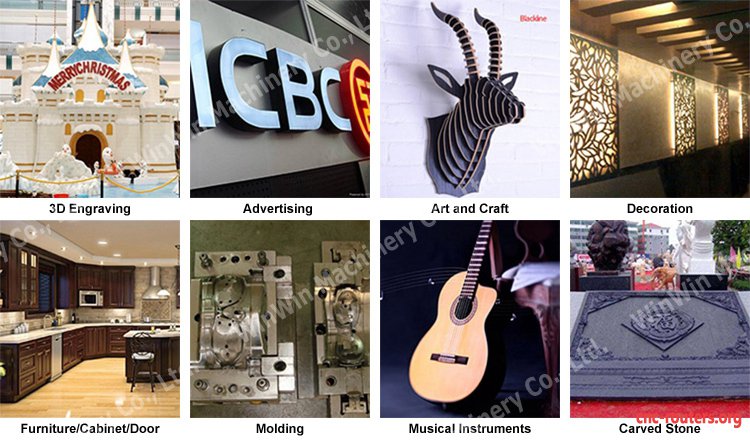

Applications

3D Carving, Acrylic Fabrication, Aluminum Fabrication, Architectural Millwork, Cabinetry, Exhibits and Fixtures, Signmaking, Arts and Crafts, Furniture, Boat Building, Musical Instruments and More.

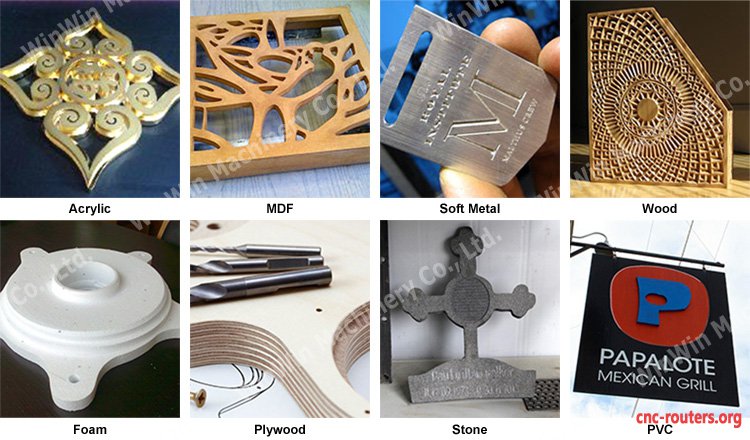

Materials

Acrylic, ACM, Copper, Brass, Aluminum, PVC, MDF, Melamine plastic, Foam, Melamine, Phenoic, Plywood, HDPE, Solid Surface, Solid Wood, etc.

Features

Specification for WW1325B CNC Router

NO. Description Parameter

01 X,Y,Z Working Area 1300x2500x200mm

02 Table Size 1360×2940mm

03 X,Y,Z Traveling Positioning Accuracy ±0.03/300mm

04 X,Y,Z Repositioning Accuracy ±0.03mm

05 Table Surface Vacuum and T-slot Combined (Option: T-slot Table)

06 Frame Welded Structure

07 X, Y Structure Rack and Pinion Drive, Hiwin Rail Linear Bearings

08 Z Structure Hiwin Rail Linear Bearings and Ball Screw

09 Max. Power Consumption (Without Spindle) 3.2Kw

10 Max. Rapid Travel Rate 33000mm/min

11 Max. Working Speed 25000mm/min

12 Spindle Power 3.0/4.5/6/7KW

13 Spindle Speed 0-24000RPM

14 Drive Motors Stepper System

15 Working Voltage AC380V/50/60Hz,3PH (Option: 220V)

16 Command Language G Code

17 Operating System DSP System (Options: Ncstudio/Mach3 PC Software)

18 Computer Interface USB

19 Flash Memory 128M(U Disk)

20 Collet ER25

21 X,Y Resolution <0.01mm

22 Software Compatibility Type3/UcancameV9 Software (Option: Artcam software)

23 Running Environment Temperature 0 - 45 Centigrade

24 Relative Humidity 30% - 75%

25 Packing Size 3300X2100X1970mm

26 N.W. 1200KG

27 G.W. 1450KG

28 Optional Parts Air Cooling Spindle or Water Cooling Spindle

Syntec Control System

Dust Collector/ Dust Hoods for three Axis

Vacuum Pump

Rotary System

Mist-cooling System

850W Yaskawa/800W Panasonic Servo Motors

Machine Schematic

1. Spindle

1.1 Manual Change Spindle