Automatic Welding Machine

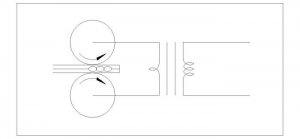

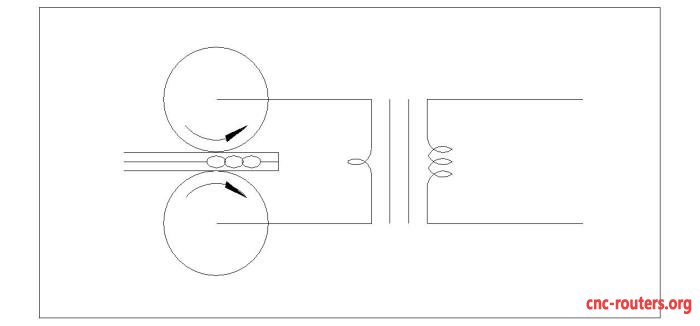

This welding machine consists of machine frame, main driving parts, welding transformer parts, welding parts, copper wire cleaning parts, cleaning parts for copper string drive, copper wire tension parts, copper string flattening parts, copper wire cutting parts, rolling parts, can feeding parts, lift-and-descend parts for can feeding, pressing parts, pulling parts, overlap tool, upper electrode press parts, upper welding arm regulating parts, diameter sizing gauge, pillar parts for diameter sizing gauge, can quitting parts, gas & water pipeline, inverters, electric & pneumatic controller etc. Welding Principle As the drawing shows,the principle is as follow:A pair of circumgyrating upper and lower welding rollers press the tinplate, by going through low voltage and high current to create heat and welding points on overlap. During the processing procedures, the copper wire acts as the media electrode, which can prevent polluting the welding rollers from the melting tinplate during process and take away the heat of the welding rollers. Because melt joints between tinplate and copper wire are continuous, the quality of welding line is good and the upper and lower welding rollers do not need to be trimmed in quite a long time. Furthermore in order to make an even touch between copper wire and welded material, the round section copper wire is required to be pressed into flat section copper wire.

Main Feature:1. Equipped with the most advanced human-computer-infer-face device, the whole operation can be made on the touch screen.2. Equipped with the servo motor controlling system, different types of inverter waves are available to change to fit the different sheets.3. Equipped with electronic static adjustable inverter power supply.4. Equipped with failure self-detected system, system alarms automatically and provides the solution proposal5. Equipped with copper wire profiling roller in ceramic, improve the insulation quality and lower the consumption.6. Equipped with the very durable ceramic unit on the can conveying system to reduce wear out.7. Equipped with the standard mercury lower welding roller, the non-mercury welding roller also available as an option.8. Lower welding arm available for both internal powder coating and internal liquid spraying coating with Nordson pump.9. Induction drying oven is available for the can line, it is able to save over 90% of energy when comparing to the gas oven.

Technical Parameter:

Welding Speed 10-70m/min

Production capacity 60-600cans/min

Stitch Range 0.5-0.9mm

Overlap 0.25-0.4mm

Can diameter 202(Φ52)-701(Φ189mm)

Can body height 60-260mm

Can body material Tinplate,Ni Plate

Material thickness 0.14-0.28mm

Tin coating TIN 5#-100#

Temper T2.5-DR8

Copper wire diameter Φ1.24mm,Φ1.38mm

Power supply 3Phases/380V

Frequency: 50Hz

Welding frequency 200-750Hz

Chilling water 500kpa,12-18℃ 20L/min

Compressed air 500kpa,800L/min

Dimension 3000 X 3200X 2200mm