Product Detail

Company Info

Quick Detail

Place of Origin

China [CN]

Brand Name

assembly line

Model Number

flason

HS-CODE

-

Package & Delivery Lead Time

Package

vacuum package

Delivery Lead Time

30 days

Detailed Description

High Speed Hanwha Automatic SMT Assembly line

High Speed Hanwha Automatic SMT Assembly line

Product Features:

High Speed Hanwha Automatic SMT Assembly line, with 2 Hanwha HM520 and 1 SM481 plus, the production speed can be around 200000 CPH. really fast for Mobile phone, LED light production, communication, LCD TV, STB, family cinema, vehicle electronics.

1. High Speed Hanwha HM520 pick and place machine.

Hanwha HM520 modular Chip mounter, it's Hanwha's first modular chip mounter, 890MM length.

Equipment size:2370x1440x890mmPower AC200 / 208/220/240/380Equipment weight:1605KG2. Samsung multifunction Chip Mounter SM481

Samsung SM481 Chip Mounter is based on the high-speed placement machine SM471 platform for the VISION system to strengthen the same level of equipment in the fastest equipment, It is equipped with a cantilever 10 shaft, the new flight camera and the application of the best suction / placement action, so as to achieve the same level of products in the world as

fast as 39,000CPH. The other can correspond to a minimum of 0402 components to the

maximum 42mm IC, and increased practical productivity and mounting quality by applying

electric feeders, which can be shared with SM pneumatic feeders, thus maximizing

the customer's convenience of use.

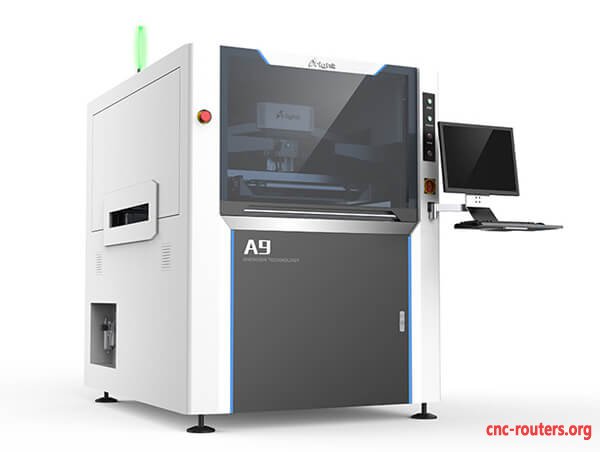

3. High Accuracy A9 SMT stencil printer.

A9 Solder Paste Printer Fully Automatic-Good Price! Good Quality! Good Service!High Accuracy smt stencil printer, which can satisfy the printing process requirements of 03015,0.25pitch high precision and high speed.

A Seriel SMT Stencil printer is high accuracy and high stability of the fully automatic printing machine vision,We followed in SMT industry is the development trend of production of a new generation of fully automatic printing machine with the international leading technology synchronous vision, visual processing of high resolution, high precision of the transmission system, suspension adaptive scraper.Specification :A Series High Precision Automatic Solder Paste Printer designed for high precisionsteel mesh printing or stencil printing in SMT industry.Printing PCB size:50mm x 50mm ~1200mm x 800mm;PCB thickness: 0.4mm ~ 14mmFPC thickness: ≦0.6mm (Excluding jig)Applicable pitches of ComponentsSMT Components such as resistors, capacitors, inductors, diode and triode: 0201, 0402, 0603, 0805, 1206 and other specifications;IC: support SOP, TSOP, TSSOP, QFN packaging, min. pitch 0.3mm; support BGA, CSP packaging,min. ball 0.2mm;Applicable PCB TypesApplicable to PCB types of mobile phone, communication, LCD TV, STB, family cinema, vehicle electronics,medical power equipment, aerospace and aviation, besides general electronics products.<span style="box-sizing: border-box;" font-size:16px;color:#000000;"="">

4. High output 6 meter 10 heating zones R10 reflow oven

1. Windows XP platform, user friendly interface and easily swap between bilingual of English & Chinese.

2. Digital control system adopted with PLC and Modular circuit. Achieving high stability and repeatibility.

3. Intelligent diagnostic system (IDS) provides trouble remind, fault alert, list-out and SPC data record features.

4. Zone temperature and blower speed can be controlled Independently, to meet the high-precision requirements.

5. Effective heating zone length with uniform heat distribution.

6. Forced air cooling system with efficient cooling speed suits most kinds of lead-free soldering application.

7. PLC and PID closed loop control to achieve high precision temperature control.

8. Standard 10 couples of top and bottom zones with patented air management structure, more efficient hot air convection and faster thermal compensation.

9. The rail track is dealt with hardening process to make it more reliable.

10. Manual adjusted process track width whereas providing option of automatic by SPG gear motor.

11. Computerized controlled rail chain lubrication structure.

12. Powerful software system can save all settings and data printout capability.

13. Flux removal unit meet with environmental protection requirement.

14. Nitrogen structure is an option.

Keywords: