3D AOI Machine

3D AOI Machine:Product Detail Company Info Quick Detail Place of Origin China [CN] Brand Name BISMT Model Number 3D AOI HS-CODE 9031-41 Package nbsp; Self-diagnostic System Sakis predictive and preventive maintenance management system assures stable machine conditions...

Stepper motor for cnc machine, cnc motor

JUKI RS-1R Pick and Place Machine

Dual Lane Wave Soldering Machine KTU-350D

Please click on the button

Know more to find out the real product information.

Product Detail

Company Info

Quick Detail

Place of Origin

China [CN]

Brand Name

BISMT

Model Number

3D AOI

HS-CODE

9031-41

Package & Delivery Lead Time

Package

vacuum package

Delivery Lead Time

30 days

Detailed Description

3D AOI Machine

3D AOI Machine

Specifications:

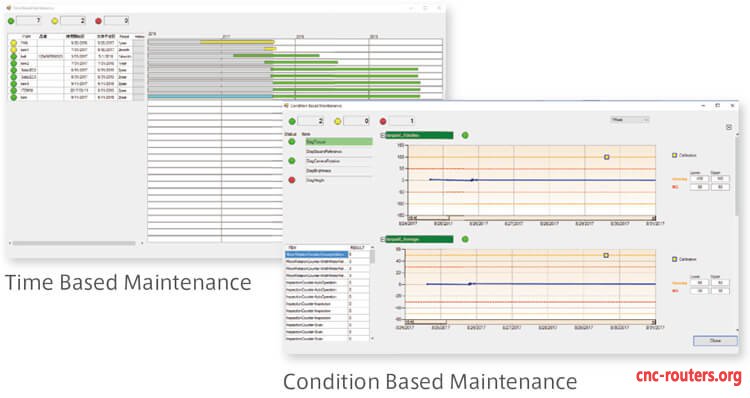

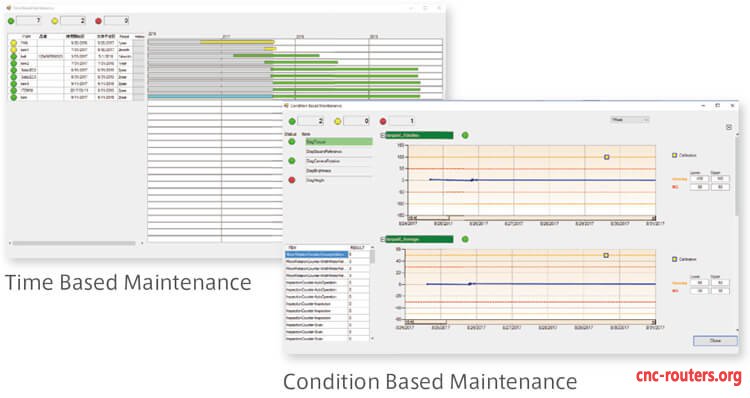

Self-diagnostic System

Saki's predictive and preventive maintenance management system assures stable machine conditions and repeatable, consistent performance. Every key component is monitored along with system conditions, and a detailed diagnostic log is recorded. The optimized preventive maintenance plan reduces maintenance time, machine down-time, manpower, and costs.Optical Unit

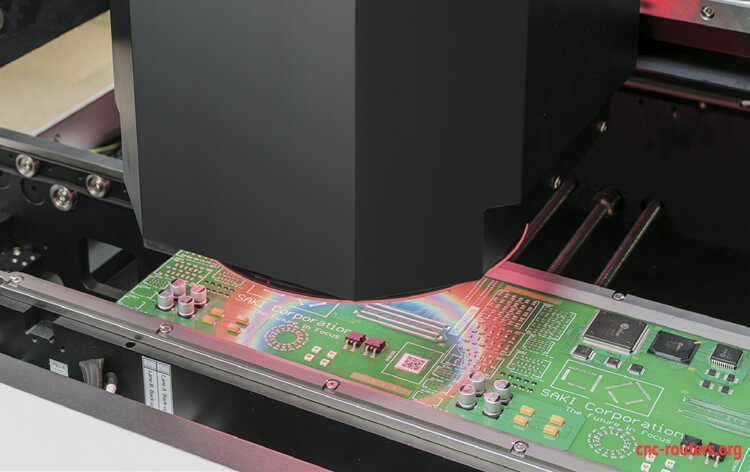

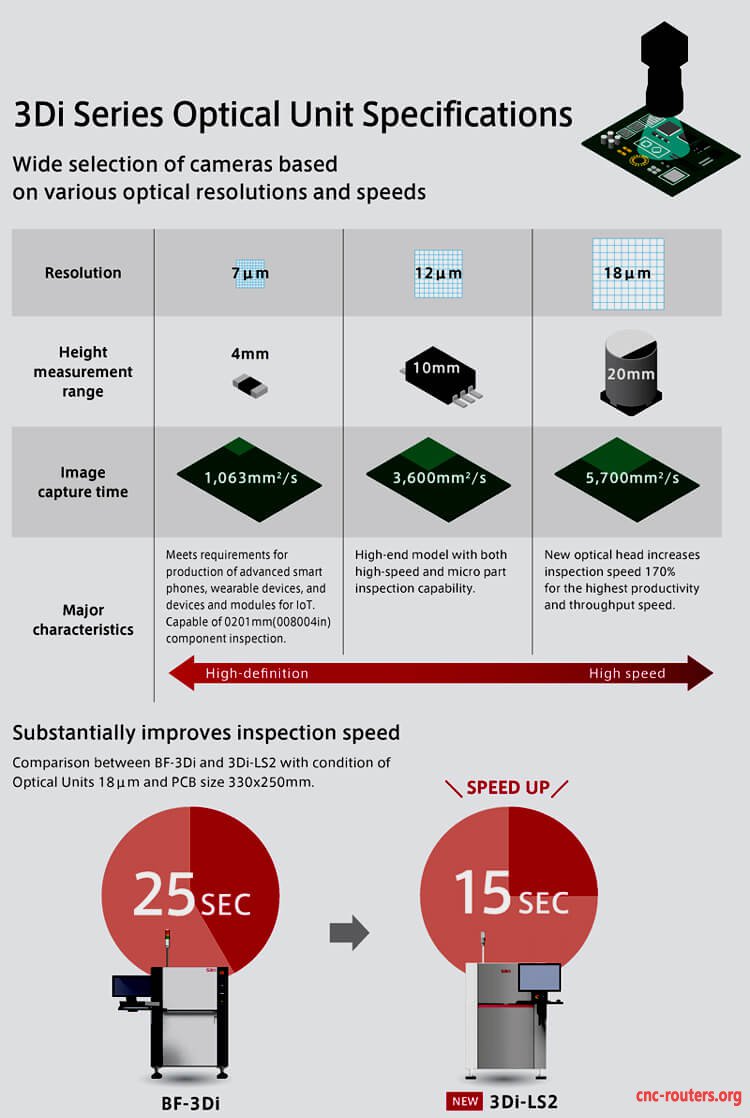

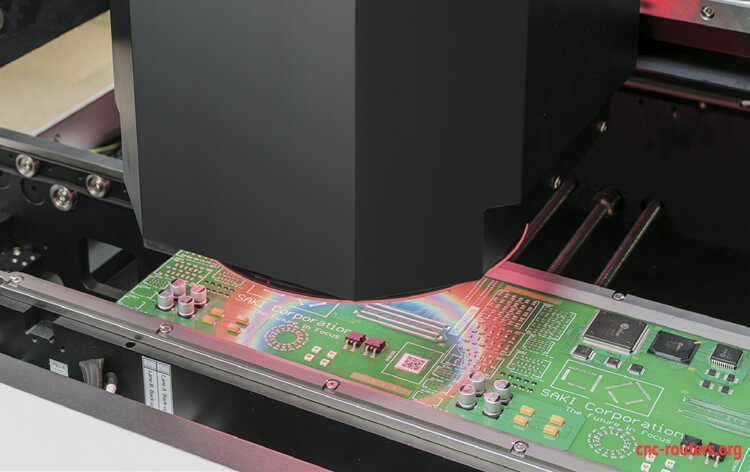

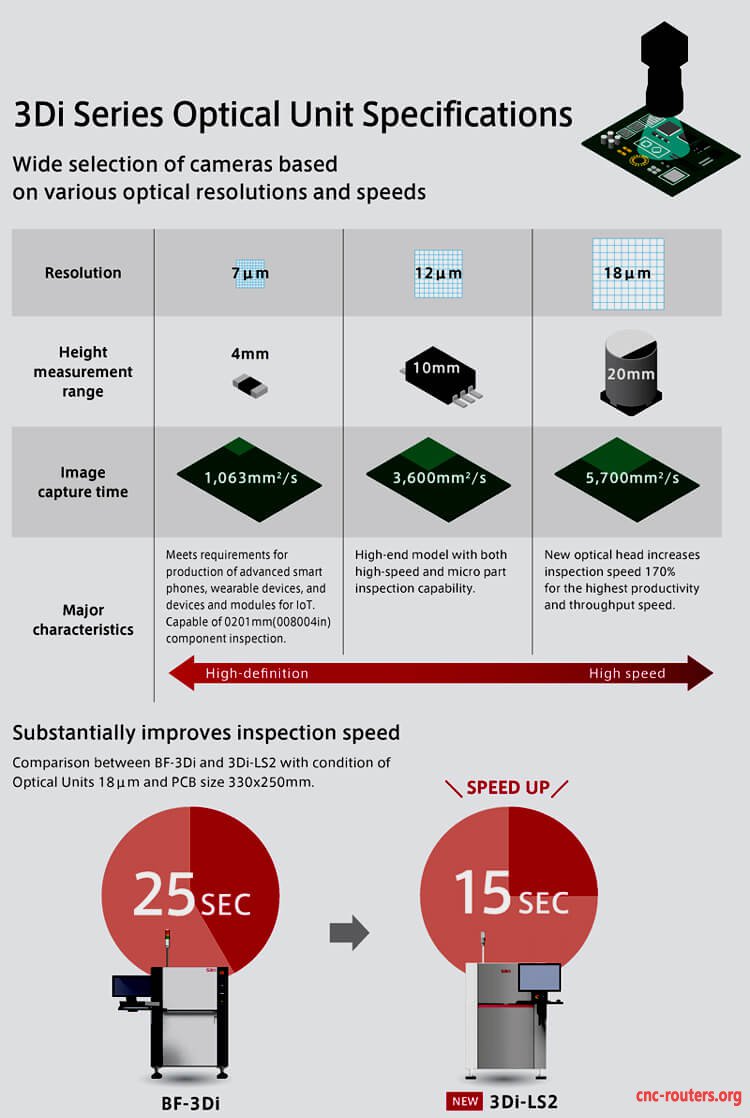

Four, multi-frequency digital projectors provide accurate 3D measurements for high-quality images.

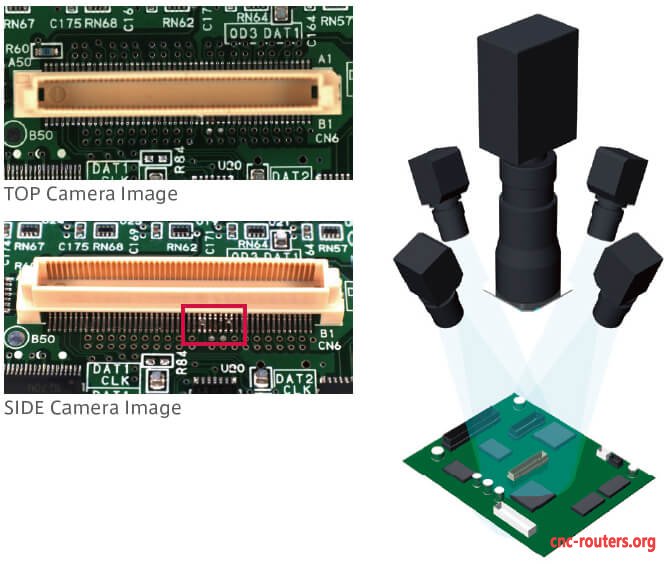

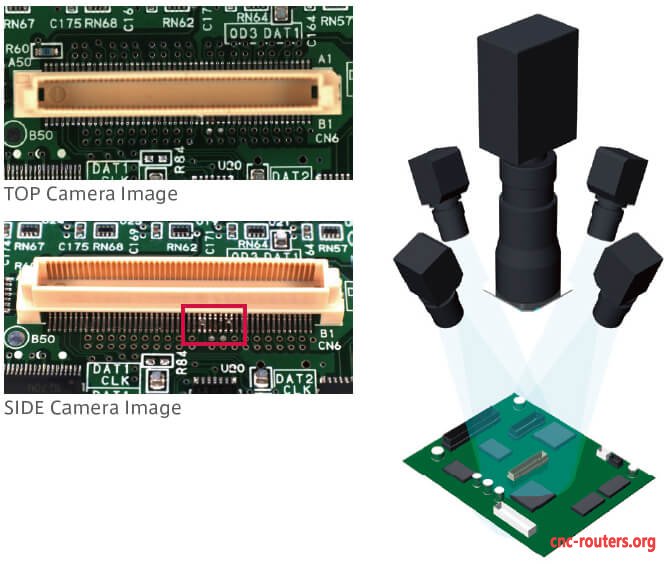

Side Cameras*

A quad side camera system ensures inspection of the entire board, including dead angles and areas missed by overhead cameras. *factory-installed option

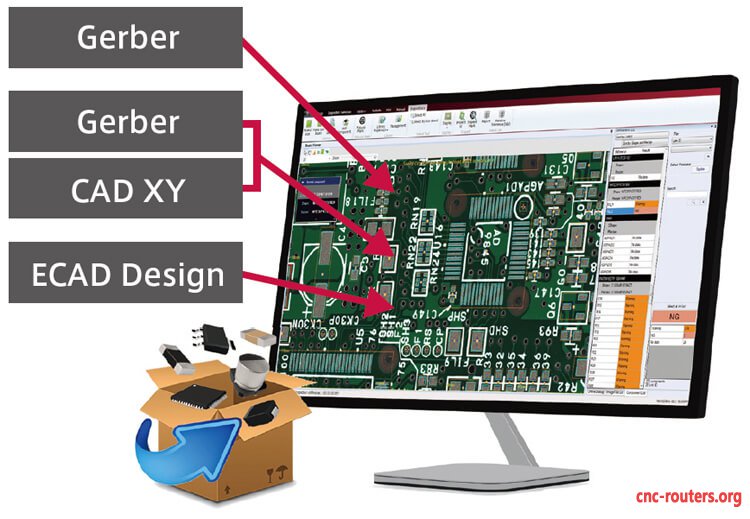

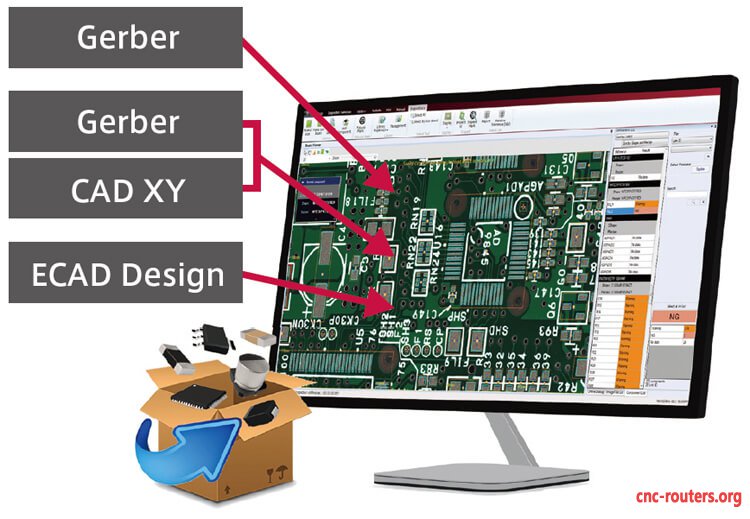

2: Advanced Software FeaturesProgramming

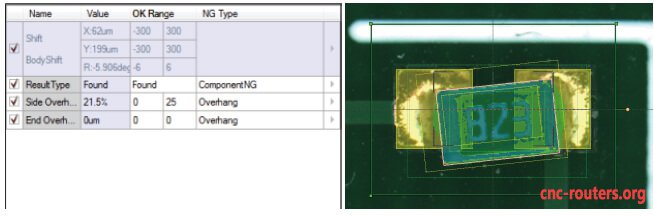

Inspection Data per IPC StandardsDefault thresholds of inspection data conform to IPC standards.

Measurement inspection and tuning function

Offline Debugging: Operator can edit inspection data to check previous Good/NG images, or real-time defect images, offline without any production interruptions.

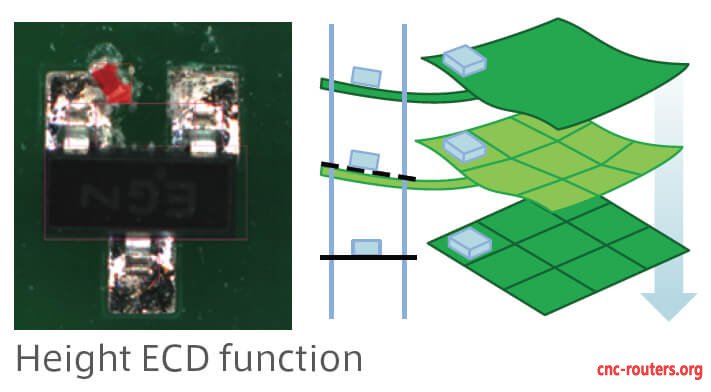

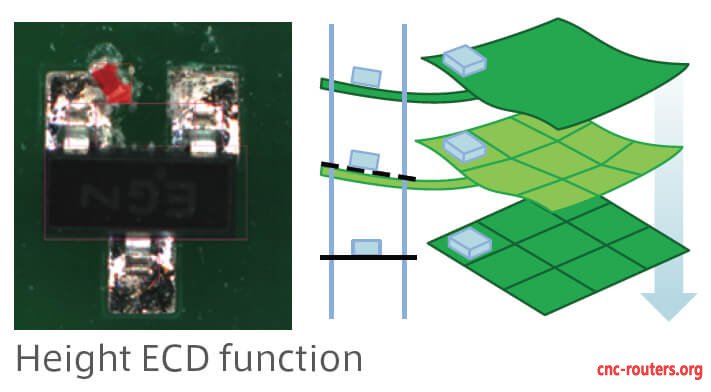

Warpage Adjustment: Warpage is compensated automatically. An accurate height map is made of the entire PCBA surface, enabling the Extra Component Detection function to detect foreign material.

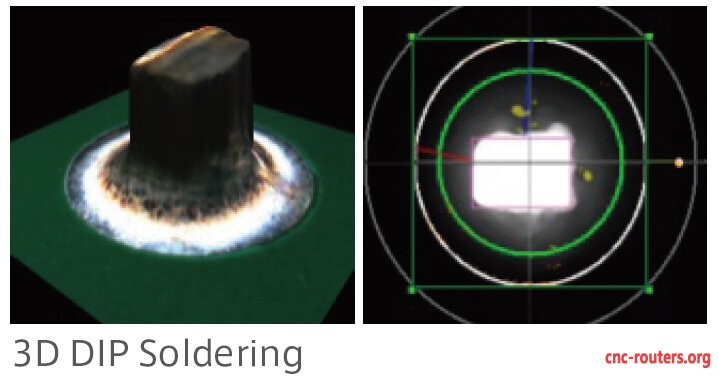

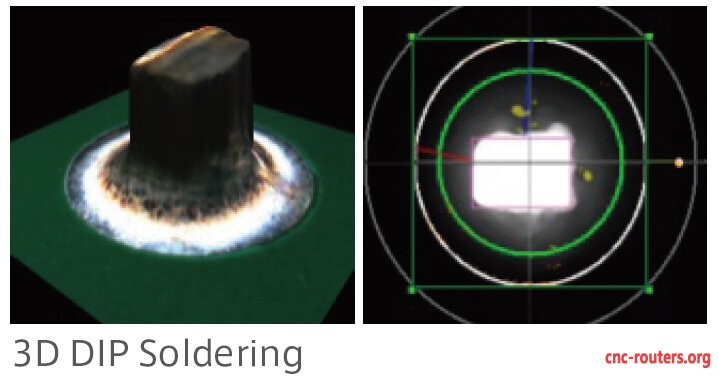

Fujiyama (Through-hole device Solder Inspection):The Fujiyama algorithmprovides complete through-hole joint inspection in a single step.It simultaneously inspects for copper exposure, pin detection, pin-holes, solder fillets, and bridges.

Inspection Data VerificationHistory Management System: The History Management System records the detailed data modification system in detail (who, what, when, where, why, and how)."Golden-Silver Board Function" Maintains inspection accuracy by checking machine status and inspection conditions before starting auto operation.

3: Applied TechnologyMachine-to-Machine (M2M) Solution

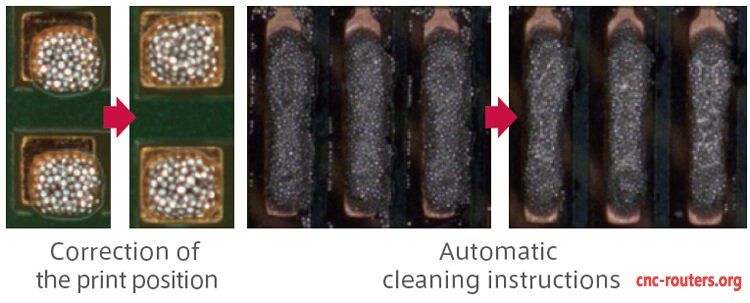

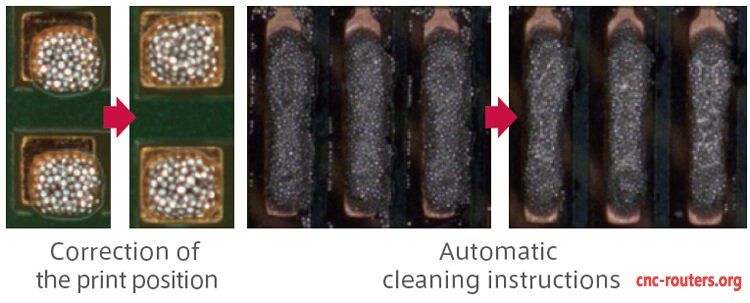

1.Feed-back from SPI to Screen Printer. Feeds back misalignment data and prevents print errors by automatically alerting the user when the stencil needs cleaning.

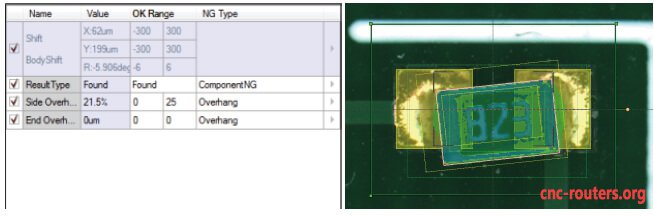

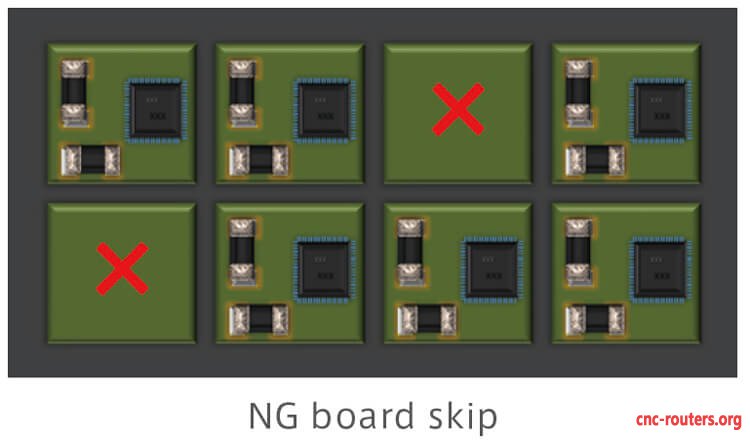

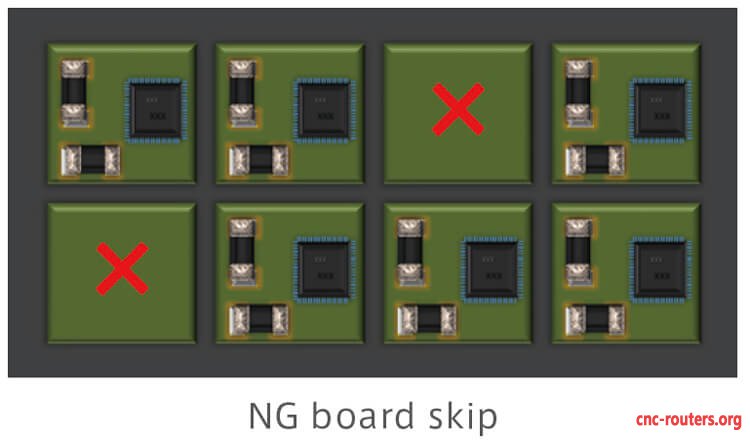

2.Feed-forward from SPI to Pick-and-Place machine. Measures the degree the printing position shifts to correct placement positioning. A NG board skip function improves efficiency, quality, and cost.

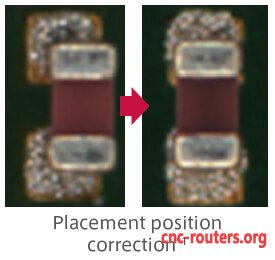

3.Feed-back from AOI to Pick-and-Place machine. Feeds backplacement position and location data from AOI to pick-and-place and feeds forward data from SPI to improve quality and efficiency.

4.Automated line control function. Automates control of the assembly line to reduce rework and waste and increase throughput.

* For items 1-4 above, Saki partners with the leading PCB equipment manufacturers. Ask us which products we connect with.OptionsBF2-EditorCreate data and debug the process offline.BF2-Monitor (Offline verification terminal)RMS (Remote Management System). Remotely control multiple BF2-Monitors with a single PC. Reduces assembly-floor personnel. Moreover, the production status of each device can be confirmed.MPV (Multi Process View). The BF2-Monitor shows the results of all inspection processes (SPI, pre-reflow, and post reflow) on one screen in real time for operator review, simplifying the verification process and making it less subject to error. It is also useful for analyzing the cause of a defective board.3Di Series Product SpecificationsDual-lane system can inspect 2 different PCBAs simultaneously

3Di Series Optical Unit Specifications

Keywords: